Thermtest Instruments Guarded Heat Flow Meter (GHFM-01) Model:GHFM-01

The GHFM-01 Guarded Heat Flow Meter is designed to test the thermal resistance and thermal conductivity of both homogeneous and heterogeneous materials.

Best For Metals, Polymers, Composites, and Pastes.

Best For Metals, Polymers, Composites, and Pastes.

-

The Guarded Heat Flow Meter (GHFM-01) follows ASTM E1530-19 for testing thermal resistance and thermal conductivity of solids, such as metals, polymers, composites and paste from -20 °C to 310 °C. The Thermtest proprietary testing stack, replaces the traditional pneumatic movement with advanced motor control, which allows automated control of testing sample thickness, force or pressure applied.

∎ Features

The advanced GHFM-01 is a primary measurement of thermal resistance—thermal conductivity for solids, such as metals, polymers, composites and paste. Specifically, the calculation of thermal conductivity from measurement of thermal resistance is the most accurate method of testing the true thermal conductivity of heterogeneous materials. The steady-state measurement of thermal resistance represents the full sample thickness and mature heat transfer properties.

According to the method, the sample is subjected to a steady-state through-thickness temperature gradient. The thermal conductivity of the sample is obtained by measuring the temperature difference across it, and one additional temperature.

The testing stack is made up of a heater – upper plate, with integrated temperature sensor and heat sink—lower plate with integrated temperature sensor on each side of the sample. Additional temperature sensors are placed near the top and bottom surface of the sample.

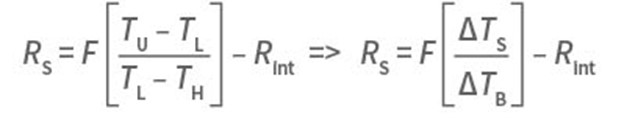

Once steady-state temperature across the sample is achieved, the Fourier law equation can be applied. The ratio RS (m2•K/W), equal to the thickness of the sample, d (m) to its thermal conductivity, λ (W/m•K), can be obtained from the temperatures measured:

The above equation is linear in form, and is the working equation of the instrument. Constants F (m2•K/W) and Rint (m2•K/W), can be obtained by calibration of the instrument. To this effect, calibration samples of known thermal conductivity and hence, thermal resistance, are employed. Calibrated results for thermal resistance and thermal conductivity are reported.- Basic and advanced functions are easy with GHFM-01 Windows Software.

- Full computer control of GHFM-01; mean temperature, sample thickness, force or pressure applied.

- Programmable mean temperatures from -20 °C to 310 °C.

- Multiple high resolution (0.01 °C) thermocouples for accurate measurement of thermal resistance and thermal conductivity.

- Thickness is measured to an accuracy of 0.0254 mm, with use of a digital optical encoder.

- Integrated force sensor with feedback loop for controlling stepper motor.

- High performance stepper motor enables plate clamping to be automated or set to a user defined thickness – ideal for compressible materials.

- Flux modules are easily changed, with no tools needed.

- Follows international standard; ASTM E1530-19.

-

Following international standards, the GHFM-01 is designed for testing both homogeneous and heterogeneous materials.

Materials Metals, Polymers, Composites, and Pastes Type of Sensors Thermocouples (x6) Applications General Testing Direction Through-Thickness Thermal Conductivity Range 0.1 to 100 W/m•K Measurement Time 40 to 60 min Accuracy ± 3% Repeatability ± 1 to 2% Plate Temperature Range -20 to 310 °C Pressure Automated up to 7 KPa (55 psi) Sample Diameter 50 to 50.8 mm Sample Thickness Up to 25 mm | Thin-films down to 0.1 mm with optional Software Standard ASTM E1530-19

*Above 60 W/m·K, the material should be a minimum of 12.5 mm thick

*Chilled circulator included with each system

-

- Anisotropic Carbon Fiber Composites

- Layered Carbon Fiber Composites

- Heterogeneous

- Compressible

- Specialized Testing Cells