Thermtest Instruments Heat Flow Meter (HFM-100 HT/HFM-100/HFM-50) Model:HFM-100 HT/HFM-100/HFM-50

Heat flow meter for measuring the thermal conductivity and thermal resistance of insulation and construction materials.

Best For insulation products, construction materials, packaging, and assemblies.

Best For insulation products, construction materials, packaging, and assemblies.

-

The Heat Flow Meter is an easy-to-use technique for measuring the thermal resistance and thermal conductivity of insulation products, construction materials, packaging and assemblies. Thermal conductivity is the measurement of the ability of a material to conduct heat and can be critical for defining energy efficiency and thermal performance in materials. Our HFM series was designed and engineered to combine the highest accuracy, repeatability, widest temperature range and industry leading performance all at an exceptional value.

∎ Features

The second generation HFM-100 / HFM-100 HT / HFM-50 instruments are an excellent choice when making steady-state thermal conductivity measurements of specimens like insulation products and construction materials. We’ve rigorously engineered the Heat Flow Meter (HFM) to meet the requirements of international standards including ASTM C518, ASTM C1784, ISO 8301, JIS A1412, EN 12667 and EN 12664. Operating the HFM is straightforward—a sample is positioned between two heating and cooling plates. The upper plate, powered by stepper motors positioned in each corner, lowers to contact the top of the sample. Plate contact with the test specimen is controlled by a standard applied pressure, or by a user defined specimen thickness.

Stepper motors are controlled by individual optical encoders for the measurement of sample thickness (L), to the nearest 0.05 mm (0.0019 in). Integrated logic between stepper motors allows the upper plate to sense and adjust for specimens with surface variations, optimizing plate – specimen contact for measurements. One heat flux sensor is integrated into each plate, and is used to monitor heat flux (Q/A), generated due to the difference in temperature (ΔT) between the top and bottom plate at regular intervals, until steady-state heat flux is observed. The composite heat flux is then used to measure thermal resistance (R) and calculate thermal conductivity (λ) according to Fourier’s Law.

- Factory calibrated

- Two flux sensors with surface thermocouples for accurate measurement of thermal resistance and thermal conductivity

- Multiple Peltier heating / cooling plates for rapid control of temperature

- Thickness is measured to an accuracy of 0.05 mm (0.0019 in) with the use of four digital optical encoders

- Front panel operation allows full control of all HFM functions, or use the new feature packed HFM-100 / HFM-100 HT / HFM-50 Software for basic and additional functions, such as printing and exporting

- Plate clamping can be automated or set to a user defined thickness—ideal for compressible materials

- Follows international standards: ASTM C518, ASTM C1784, ISO 8301, JIS A1412, EN 12667, and EN 12664

-

Following international standards, the HFM-100 is designed for testing both homogeneous and heterogeneous materials. The HFM-100 / HFM-50 sample size allows for representative testing of materials typically found in insulation and construction industries.

Materials Insulation, Solids, and Textiles Type of Sensors Flux Sensors (x2) Surface Thermocouples Three for each flux sensor Applications General Testing Direction Through-Thickness Factory Calibrated Yes Thermal Conductivity Range 0.002 to 0.5 W/m•K Specific Heat Capacity Optional High Thermal Conductivity Kit Up to 2.5 W/m•K Measurement Time 30 to 40 minutes Reproducibility ± 0.5 to 1% Accuracy ± 1 to 2% HFM-100/HFM-50

Plate Temperature Range-20 to 75°C (-4 to 167˚F) HFM-100 HT

Plate Temperature Range-30 to 110 °C (-22 to 226˚F) HFM-100 / HFM-100

HT Sample SizeUp to 300 x 300 x 100 mm (12 x 12 x 4 in) HFM-50 Sample Size Up to 200 x 200 x 50 mm (8 x 8 x 2 in) Standard ASTM C518, ASTM C1784, ISO 8301, JIS A1412, EN 12667, and EN 12664

Method is continually improved; specifications are subject to change without prior notice.

*Performance verified with NIST 1450d / 1450e

*Chilled circulator required -

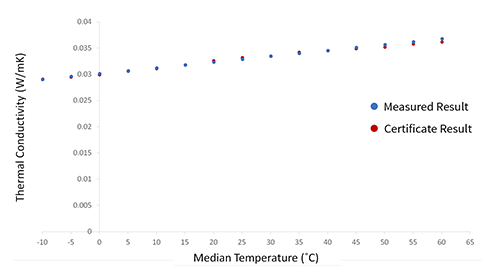

The Thermtest HFM-100 is capable of testing materials over a temperature range of -20 to 75°C (-4 to 167˚F). NIST 1450d, Fibrous Glass Board, is a certified Standard Reference Material from the National Institute of Standards, and Technology. Measured results are within 2% of the certified values.

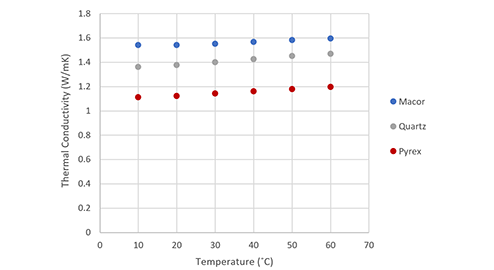

With the added High Thermal Conductivity Kit, the HFM-100 / HFM-50 are able to accurately and efficiently measure higher thermal conductivity materials, such as glass and ceramics. For such applications, an external thermocouple kit is used in combination with the sample being tested. Macor, Quartz, and Pyrex were tested in the HFM from 10˚C to 60˚C (50˚F to 140˚F). All measured values are within the stated accuracy of the system, ± 5%.

-

Batting Insulation

-

Aerogel

Aerogel has one of the lowest thermal conductivities known to solids. An aerogel blanket of choice was selected to test by the Heat Flow Meter. Results concluded a thermal conductivity of 0.014 W/m•K, which is within 3% to the manufacturers specification.- Wood

As wood is rigid, the HFM can be set to automatically adjust to the height of the sample. Testing of this softwood produced a thermal conductivity reading of 0.12 W/m•K, an exact match to the literature values for softwoods. -