The Infrared Thermal Desorption Analyzer TDS1200Ⅱ Model:TDS1200Ⅱ

The infrared heating type temperature-controlled thermal desorption analyzer TDS1200Ⅱ is an analyzer that utilizes a spectrometer to provide real-time observation of the molecules desorbed during the programmed temperature control of the sample in an ultra-high vacuum. Components with high background levels, like water, hydrogen, oxygen and carbon dioxide, can be detected, even in trace amounts, because the measurements are performed in a vacuum. Suitable for measurements in which infrared heating is easy to perform, such as thin film samples and samples with a thin sheet form.

-

∎ Features

The infrared heating type temperature-controlled thermal desorption analyzer TDS1200Ⅱ is an analyzer that utilizes a spectrometer to provide real-time observation of the molecules desorbed during the programmed temperature control of the sample in an ultra-high vacuum.

Components with high background levels, like water, hydrogen, oxygen and carbon dioxide, can be detected, even in trace amounts, because the measurements are performed in a vacuum.

The chemical species can be identified and quantified for the molecules desorbed from the sample. Information like the absorption/bonding state and diffusion process of the desorbed gas can also be obtained.

Suitable for measurements in which infrared heating is easy to perform, such as thin film samples and samples with a thin sheet form. The new TDS1200II incorporates a renewed version of the TDS1200 system and a touch panel interface. Satisfies the standards for CE marking.

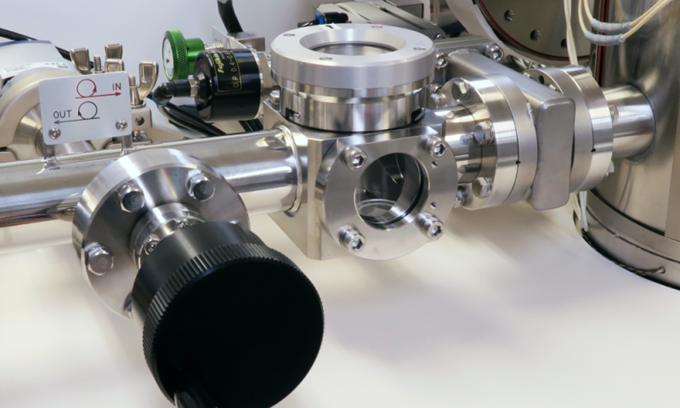

The load-lock chamber

The load-lock chamber is essential for achieving high sensitivity and high-efficiency (high throughput) measurement. Our load-lock chamber and sample transfer mechanism enable quick insertion of only the sample into the analysis chamber under an ultra-high vacuum.

If there is no load-lock chamber, it is necessary to expose the analysis chamber to ordinary atmosphere each time the sample is exchanged. A large amount of air (mainly water) is drawn into the analysis chamber when it is exposed to ordinary atmosphere, making it necessary to perform evacuation for a long time to return to a suitable vacuum level.

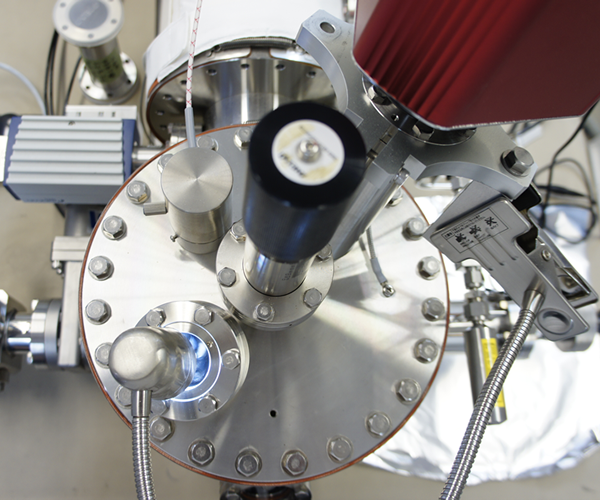

Infrared heating method

For thermal desorption analysis it is important not to heat the analysis chamber or parts inside the analysis chamber when the sample is heated. If the chamber is heated during TDS it is difficult to distinguish between the gases desorbed from the sample and the gases desorbed from the chamber.

TDS1200II directly heats the sample with infrared radiation introduced via a quartz rod, enabling increases in the background level to be suppressed, even in the high temperature range, providing high-sensitivity measurement.

QMS ionization chamber arrangement

To detect the desorbed gases with high sensitivity, a QMS ionization chamber is placed directly above the sample. The position directly above the sample allows the gases desorbed from the sample to reach the QMS ionization chamber directly, enabling highly sensitive detection of even materials like metals that become easily deposited and organic molecules with a high molecular weight.

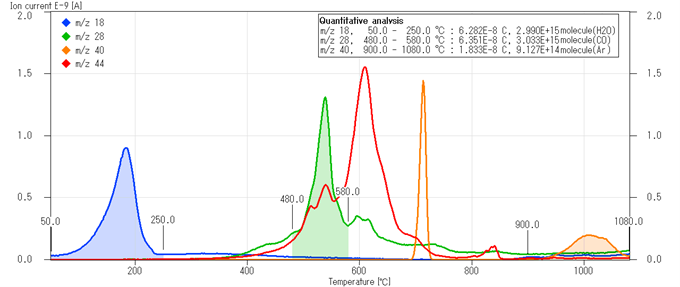

Quantification of desorbed gases

The data processing program enables quantitative analysis of the desorbed gases. To perform quantitative analysis of the desorbed gases, it is necessary to regularly calibrate the sensitivity of the mass spectrometer.

Sensitivity calibration using standard leaks requires preparation of an expensive standard leak for each type of gas, and the calibration procedure is time-consuming. In addition, strict health and safety management is required when standard leaks of poisonous gases are used.

The current quantification program enables quicker, easier, and safer quantitative analysis of the desorbed gases than the method using calibration with standard leaks. Highly accurate results can be obtained simply by periodically measuring the NIST-traceable hydrogen standard sample produced by ESCO. The sensitivity correction method we have developed can correct the sensitivity even for gases other than hydrogen, and it has been verified that the results obtained are in good agreement with quantitative results obtained using calibration with a standard leak according to the National Institute of Advanced Industrial Science and Technology (AIST) standards.

-

Items Specification Vacuum pressure Main chamber <5*10-7 Sample size 15*15*4 mm Temperature range 50-1200℃ Temperature increasing rate 1-180℃/min Detector QMS Sensitivity Ar 1*10" Ar/s (S/N=3) Software TDS measurement, Data Viewer, Quick CSV -

- Si-wafer outgassing analysis by thermal desorption spectrometry TDS